With the constant development of electronic devices, their internal electronic components are becoming increasingly complex and dense. These components generate a significant amount of heat during operation. If the heat is not dissipated in a timely and effective manner, it can cause the device to overheat, reduce performance, or even become damaged. Therefore, the selection and application of thermal materials is crucial. The thermal pad is a commonly used heat transfer material.

What is a Thermal Pad?

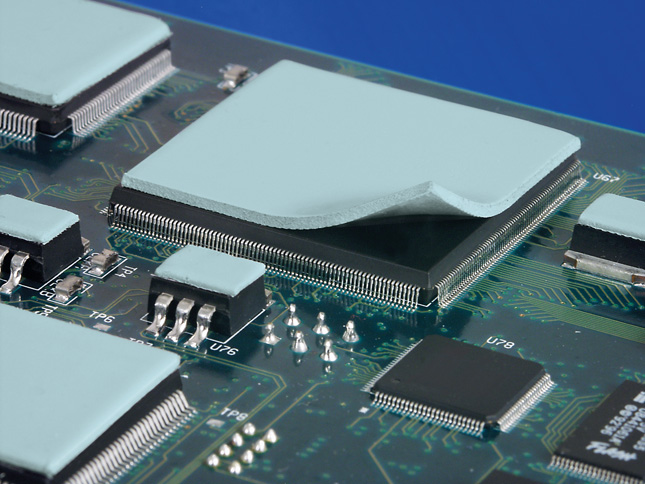

A thermal pad is a material used for heat transfer. It can be considered as a thermally conductive medium that can effectively transfer heat. The thermal pad is typically used between a heatsink and a chip or other electronic device to help transfer heat away from the device and dissipate it into the surrounding environment.

The thermal pad is often made of high thermal conductivity materials, such as silicone, graphite, or ceramic. It is usually soft and compressible, allowing it to conform to irregularities in the surfaces of the chip and heatsink. The pad is also designed to be non-conductive and non-reactive to avoid short circuits or chemical reactions that could damage the device.

The Role of Thermal Pad in Heat Transfer

The thermal pad plays a vital role in heat transfer by filling any gaps or unevenness between the chip and the heatsink. The air gaps between these surfaces can be a significant barrier to heat transfer, as air is a poor conductor of heat. The thermal pad helps to eliminate these gaps and improve the thermal contact between the chip and the heatsink, thus improving the efficiency of heat transfer.

The thickness of the thermal pad is an essential factor that affects heat transfer. A thicker pad can provide more thermal conductivity, but it can also increase thermal resistance and reduce heat transfer efficiency. A thinner pad, on the other hand, may not provide enough thermal conductivity and could result in poor heat transfer. Therefore, it is important to select the appropriate thickness of the thermal pad based on the specific application.

Types and Materials of Thermal Pad

There are several types of thermal pads available in the market, with varying materials and characteristics. The most commonly used materials for thermal pads are silicone, graphite, and ceramic.

Silicone thermal pads are the most widely used type of thermal pad. They are flexible and conformable, which makes them easy to use and install. They also have good thermal conductivity and can withstand high temperatures.

Graphite thermal pads have a higher thermal conductivity than silicone pads and are more durable. They are often used in applications that require high thermal conductivity and good mechanical stability.

Ceramic thermal pads have the highest thermal conductivity among the three types of thermal pads. They are often used in applications that require high thermal conductivity and excellent electrical insulation.

How to Choose the Right Thermal Pad

Choosing the right thermal pad requires considering several factors, including the device’s power consumption, operating temperature, and thermal conductivity. A thermal pad with high thermal conductivity is generally preferred, but it should also be compatible with the materials used in the device and the heatsink.

The thickness of the thermal pad should also be taken into account. A thicker pad may provide better thermal conductivity, but it could also reduce the efficiency of heat transfer. A thinner pad may not provide enough thermal conductivity, resulting in poor heat transfer.

It is also important to consider the size and shape of the thermal pad. The pad should be the right size and shape to fit the chip and the heatsink properly, with no gaps or overlaps.

Using and Maintaining Thermal Pad

When using a thermal pad, it is important to ensure that the surfaces of the chip and heatsink are clean and free from debris or contaminants that could interfere with heat transfer. The thermal pad should be placed on the chip and role in heat transfer. It effectively fills the gaps between the chip and heatsink, improving thermal contact and reducing thermal resistance. This leads to improved efficiency of heat transfer and prevents overheating performance degradation, or device damage.

When selecting a thermal pad, factors such as the device’s power consumption, operating temperature, and thermal conductivity should be considered. The appropriate thickness, size, and shape of the thermal pad should also be chosen based on the specific application.

To ensure proper performance, it is essential to keep the surfaces of the chip and heatsink clean and free of debris. Regular maintenance and inspection are also necessary to ensure that the thermal pad is functioning optimally.

Types of Thermal Pads: There are several types of thermal pads available, including silicone-based, acrylic-based, and ceramic-based pads. Each type has its advantages and disadvantages in terms of thermal conductivity, hardness, and durability.

Operating Temperature Range: Different thermal pads have different operating temperature ranges. It is important to select a thermal pad that can handle the specific operating temperature range of the electronic device to ensure optimal performance and prevent damage.

Size and Shape: The size and shape of the thermal pad should be carefully selected based on the size and shape of the chip and heatsink. It is important to ensure that the thermal pad fits perfectly between the two surfaces to maximize thermal contact and minimize thermal resistance.

Thickness: The thickness of the thermal pad is also a crucial factor to consider. A thicker pad can provide better heat transfer performance, but it may also increase the distance between the chip and the heatsink, leading to decreased thermal contact. The appropriate thickness should be chosen based on the specific application.

Application Method: There are different methods to apply thermal pads, including pre-cut adhesive pads and continuous rolls. The chosen method should be suitable for the specific application and ensure proper alignment and adhesion.

In conclusion, thermal pads play a critical role in ensuring optimal heat transfer and preventing device damage in electronic devices. Choosing the right type, size, and shape of thermal pads and proper application and maintenance can help maximize performance and prolong the lifespan of electronic devices.

Conductivity of Thermal Pads: The thermal conductivity of a thermal pad is a measure of how effectively it can transfer heat. A higher thermal conductivity value means that the thermal pad can transfer heat more efficiently. It is essential to choose a thermal pad with the appropriate thermal conductivity to meet the needs of the electronic device.

Durability: The durability of a thermal pad is also important, as it will determine how long it can maintain its effectiveness in transferring heat. A thermal pad that degrades quickly can lead to decreased performance or even device failure. The appropriate level of durability should be chosen based on the specific application and the expected lifespan of the electronic device.

Compatibility with Other Materials: The thermal pad should be compatible with other materials used in the electronic device, such as adhesives, coatings, or protective films. Incompatibility can lead to reduced effectiveness or even damage to the electronic device.

Environmental Factors: The operating environment of the electronic device can also affect the effectiveness of the thermal pad. Factors such as humidity, temperature, and exposure to chemicals or UV light can impact the durability and thermal conductivity of the thermal pad. It is important to choose a thermal pad that can withstand the specific environmental factors in the device’s operating environment.

Safety: Finally, safety is also a crucial factor to consider when selecting a thermal pad. Some thermal pads may contain harmful chemicals or release toxic fumes when heated. It is important to choose a thermal pad that is safe for use in the specific electronic device and follow proper safety protocols when handling and applying the thermal pad.

Related Products

CTLC120 thermal pad

CTLC120 thermal pad is a general-purpose and economical thermal conductive gap filler, cost-effective, soft and self-adhesive, easy to assemble. It shows good thermal conductivity and electrical insulation performance under low compression force. It is placed between the heating device and the gap between the heat sink or the machine shell, and the air is squeezed out to achieve full contact, forming a continuous heat conduction channel. Using the heat sink or the machine shell As a heat dissipation device, the heat dissipation area can be effectively increased, thereby effectively improving the heat dissipation effect.

CTLCV-200S SIL PAD

CTLCV-200S High thermal conductivity SIL PAD is a kind of thin thermal conductive insulating material with excellent comprehensive properties, which is synthesized by special process with glass fiber as the base material, thermal conductive powder and high molecular polymer. This material has the advantages of high thermal conductivity, high friction resistance, high tensile strength and smooth and high adhesion surface, which can greatly reduce the interface thermal resistance under low pressure. It is widely used in the situation of high thermal conductivity and high electrical insulation. It is suitable for fixing components with low tightening pressure. It is mainly used between the heating semiconductor device and the heat dissipation substrate for heat conduction and insulation.

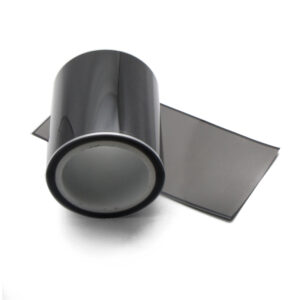

CTLGS1500 Graphite sheet

CTLGS1500 is a synthetic graphite heat sink. CTLGS1500 has a unique grain orientation, lamellar structure can be well adapted to any surface, even heat conduction along the two directions. Plane thermal conductivity of up to 1900 W/m-K. CTLGS1500 products while also the thickness of uniform heat to provide thermal isolation. Heat shielding and components while improving the performance of consumer electronics products. CTLGS1500 composite graphite sheet is a polyimide sintered novel film material with high thermal conductivity and excellent product design flexibility.